News

High integrity CompactPCI S.0 Intel Core i7 based conduction cooled solution for your mission critical application

Introduction

The integrated onboard automated control systems are currently considered as advanced and multifunctional platforms providing solutions for a wide range of tasks. In such a case, depending on the type of a vehicle, they can either assist

The need for

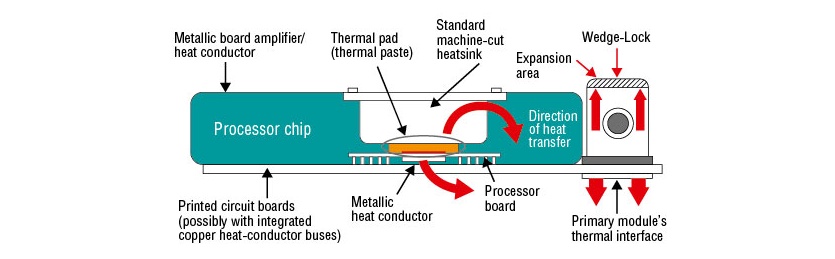

In this case the use of computing systems with conduction cooling is seen as a rather efficient solution. This simultaneously provides the system with resistance to mechanical impacts and adequate heat removal. In such a situations heat emission from electronic components is sequentially transferred via several metallic

Below is the description of Fastwel CPU modules and onboard computing system design with conduction cooling based on Fastwel CPC510 which complies with CompactPCI Serial standard.

Fastwel products

The heat removal system is one of the key factors indicating computer reliability. Using the simplified formula, computer operating life is reduced by half as the temperature increases by each 10 °С. The CompactPCI Serial standard is currently defines 2 module cooling types: convection (air) and conduction cooling.

The heat removal system is one of the key factors indicating computer reliability. Using the simplified formula, computer operating life is reduced by half as the temperature increases by each 10 °С. The CompactPCI Serial standard is currently defines 2 module cooling types: convection (air) and conduction cooling.

The system based on conduction cooling is designed for installation of modules sized: 122×162 mm (3U), with a pitch of 5HP. Dimensions of CompactPCI Serial boards with conduction cooling differ from the standard ones. These boards are based on the standard module installed into a metal enclosure. This helps to sufficiently reduce the costs for manufacturing of boards with conduction cooling.

Due to the modifiability of any CompactPCI Serial board equipped with conduction cooling into a module with conduction

Fastwel product line includes

All the modules are designed for the operation in industrial temperature range: −40…

Due to the design of modules with conduction heat removal, they often cannot be equipped with the complete set of connectors on the front panel, advanced LED- indication and extension bays. Usually all interfaces required for connection to peripheral devices, are implemented via the backplane and are located in the zone of rear I/O contacts.

CPC510 CPU module is developed for customers as the high integrity solution in CPCI Serial 3U

CPC510 CPU module is developed for customers as the high integrity solution in CPCI Serial 3U

CPC510 uses

Reliability of CPC510 makes it possible to use it in all industrial application areas. Components being the basis for CPC510, are carefully selected depending on the criteria of their applicability in harsh environments.

The module has the following structure of I/O channels:

- 2 x Ethernet 1 Gb/s controllers (2 x are routed to the front panel);

- 12 x USB 2.0 ports with support of HS, FS and LS speeds (2 x on the front panel, 2 x on mezzanine board, 8 x on the backplane connector)

- 4 x USB 3.0 ports (routed to the backplane connector)

- 6 x SATA ports (4 x ports are routed to the backplane connector, 1 x on the mezzanine connector, 1 x switchable backplane/mezzanine)

- 1x DisplayPort is routed to the MIC590 board (to the front panel of

CPC510-02 ) - 1x LVDS is routed to the MIC590 board

- 2x DisplayPort on the front panel

- HD Audio is routed to the mezzanine connector

- LPC is routed to the mezzanine connector

CPC512 CPU module (including its conduction cooling version) will be available soon. The module will be aimed at building

The CPC512 module is similar to CPC510, but has some distinctions:

- Instead of 2 x

PCI-E switch Gen 2.0, CPC512 has onePCI-E switch Gen 3.0 with increased speed of data transfer (up to 8 Gb/s) and with DMA mode support which significantly reduces CPU load during data transfer. Apart from the retained operability of PCI Express ports in NT mode, the use of the newPCI-E switch Gen 3.0 has added support of the Host failover mode (failsafe mode for two CPC512 modules) for 2 x ports x8, routed to the backplane. - 2 x ports x4, routed to the backplane, started to support the increased speed of data transfer (up to 8 Gb/s)

- Support of MIC590 mezzanine board has been stopped, this made possible to support PCI Express interface for all the slots of 8x slot backplane. Therefore, 4x PCI Express ports x1 Gen 2.0 are additionally routed to the backplane.

- Support of Gigabit Ethernet operation via backplane with Intel AMT function has been added. The AMT (Advanced Management Technology) function actually is the advanced IPMI (Intelligent Platform Management Interface). It enables to remotely control CPU module operation, change system BIOS settings, reload or turn off the system as well as support Remote Desktop function.

Conduction Cooling System Design

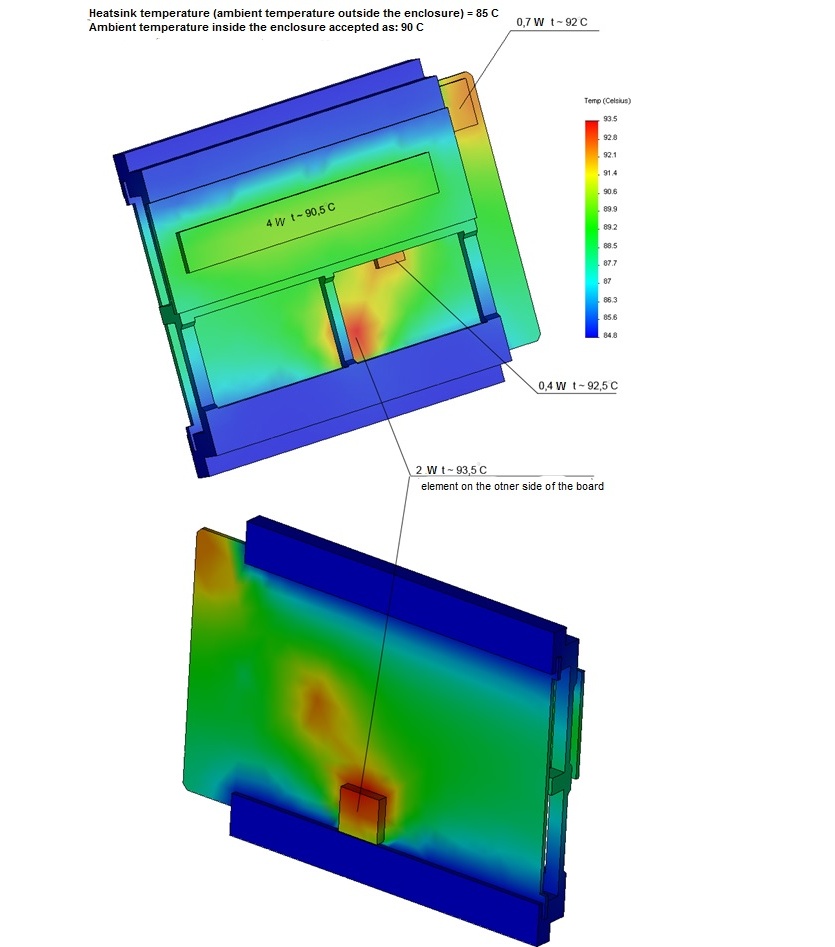

Designing and development of the conduction cooling system usually begins with estimation of heat emission system and choosing the right enclosure which provides removal of the released thermal energy. Additionally, it is necessary to consider a place for enclosure installation, requirements for mechanical and climatic effects. Basically this represents a rather challenging engineering task and usually there are no serial enclosures for systems with conduction cooling. Computers with conduction cooling are always built for particular customers and systems.

Design of the onboard computing system with conduction cooling includes: modular chassis with backplane, power supply unit and computer modules in special

Modular structure of the system based on the platform concept enables users not only to build its system in compliance with the modular principle but also provides its easy expansion and development in the future.

Modular structure of the system based on the platform concept enables users not only to build its system in compliance with the modular principle but also provides its easy expansion and development in the future.

Chassis is usually assembled from

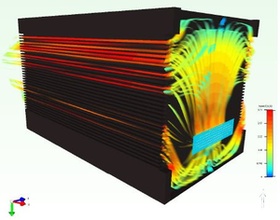

Design of the chassis should provide the most efficient contact transfer of heat from active components to the chassis enclosure. System is manufactured in metallic enclosure, but first a detailed

Why to Choose Fastwel

Fastwel customers can always contact company’s engineers during design of the systems based on Fastwel CPU boards. Engineers will help selecting the right enclosures and systems either on the basis of System Partners product line (Elma) or based on Fastwel projects. Due to the

Fastwel customers can always contact company’s engineers during design of the systems based on Fastwel CPU boards. Engineers will help selecting the right enclosures and systems either on the basis of System Partners product line (Elma) or based on Fastwel projects. Due to the

-

Sản phẩm 2018 file (6,3 mb)

Sản phẩm 2018 file (6,3 mb)

-

Sách Trắng Khoa học Kỹ thuật

Sách Trắng Khoa học Kỹ thuật

-

Blog

Blog

-

Ví dụ về Ứng dụng

Ví dụ về Ứng dụng

-

Bài báo

Bài báo